Our Converter App

The ESI Pressure converter allows you to quickly and easily access a conversion tool to work out your preferred unit of pressure measurement wherever you may be. Whether out on-site or in the office.

Download the ESI-USB© Software

The ESI-USB© software allows you to connect your ESI transducer to your laptop or PC and be up and running monitoring pressure data within ten minutes. The software auto-updates and is compatible with Windows 8, 10 & 11.

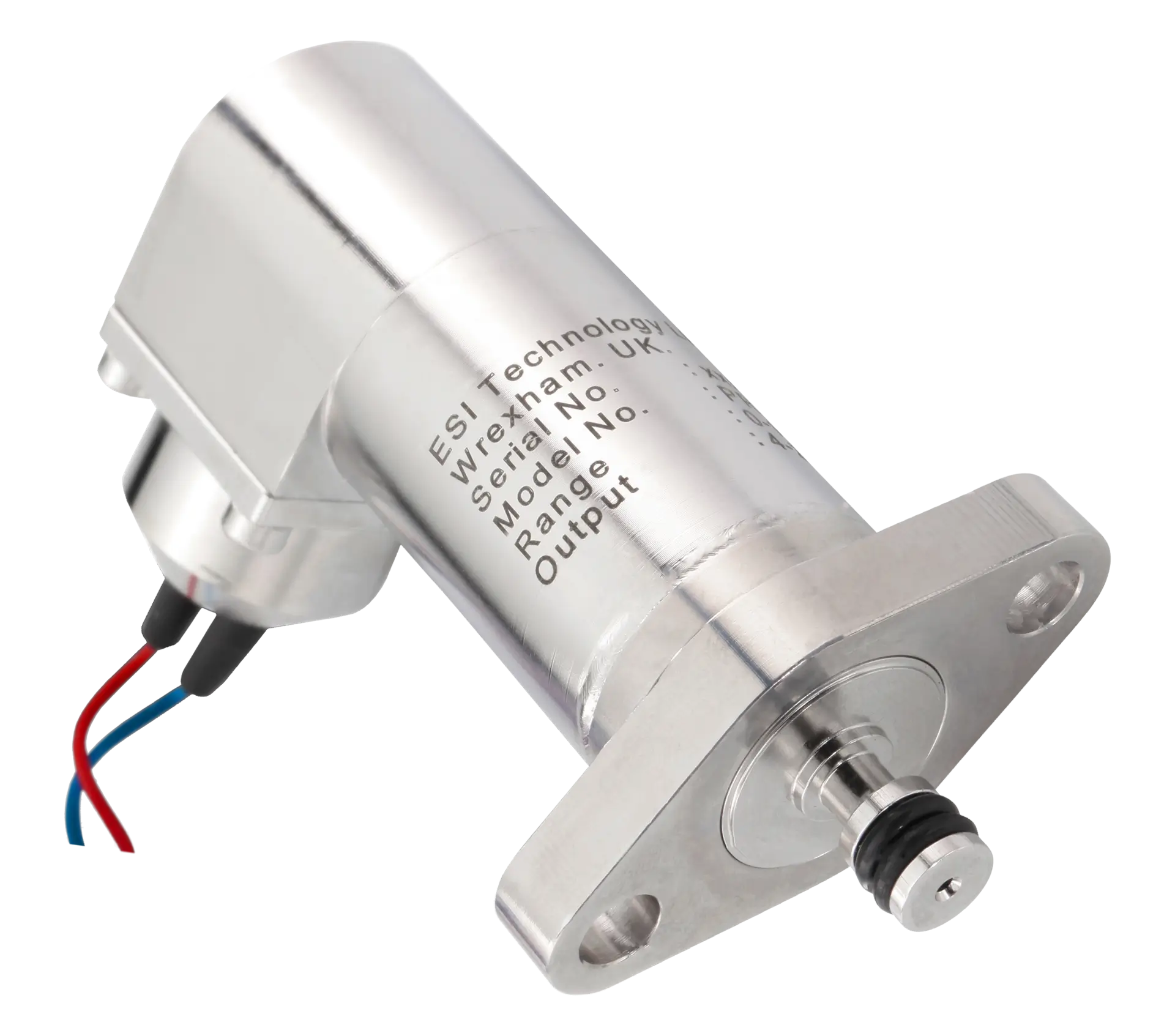

PR3920

Differential Subsea Pressure Transmitter

- Silicon-on-Sapphire sensor technology

- Standard sensing range 0-50 bar DP

- 690 bar line pressure

- 1,200 bar secondary containment

- Submersion to 3,000 mtrs sea level

- High accuracy option

- NACE corrosion resistance

- ATEX/IECEx option available

- Hyperbaric & ESS Testing and document packages available

Description

The PR3920 differential pressure transmitter provides very accurate low pressure wet-wet differential pressure measurement on extremely high line pressure sources. Designed for permanent installation in very demanding subsea applications the housing is completely sealed to resist 300 bar external pressure. Intended for submersion in pressurised dielectric oil with seawater for monitoring of subsea well control valves or hydraulic pressure measurement.

The unique Silicon-on-Sapphire sensor technology provides outstanding performance and gives excellent stability over a wide temperature range. The sensor can endure high over-pressures and provides superb corrosion resistance with virtually no hysteresis. The outstanding insulation properties of the sapphire allows the sensor to operate over a very wide temperature range without loss of performance.

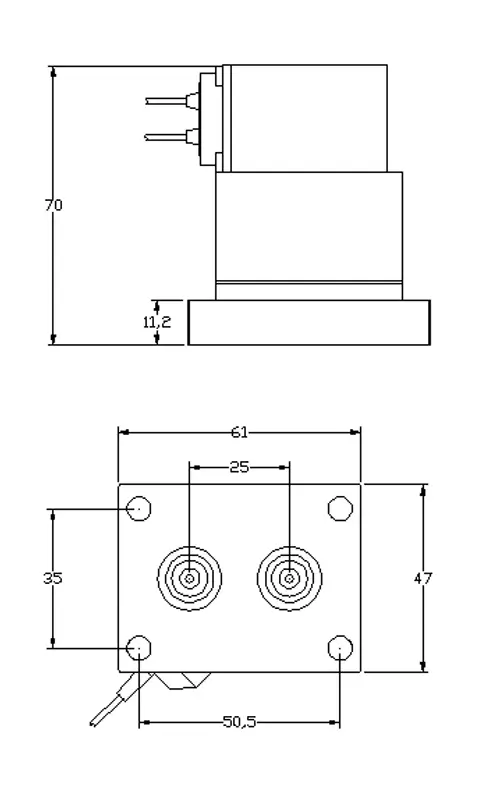

The PR3920 pressure transmitter provides surface mounting with a stainless steel mounting plate and dual redundant o-ring face seals. Both the high and low pressure ports can withstand 1,000 bar overpressure with no damage or loss of performance. The titanium alloy wetted parts provide conformance to NACE corrosion resistance requirements. Electrical connection is via a heavy duty PTFE cable with optional angle of orientation. Output signal is a 4-20 mA, 2 wire current loop which can be powered from and external 10-36 Vdc supply. Each unit is Hyperbaric tested to 3,000 metres. ESS testing and comprehensive document packages are also available.

Standard pressure ranges:

0-750psi (51 barDP)

Typical applications include:

- Control of chemical injection for subsea wells

- Hydraulic pressure measurement

- Oil and gas extraction

- Permanent immersion at subsea levels

Technical Specifications

Electrical Connections

| Wire | Function |

| Red | Supply (10-36 Vdc) |

| Blue | Signal (4-20 mA) |

Certifications

Get a quote..

For more information or to request a quote contact our sales team